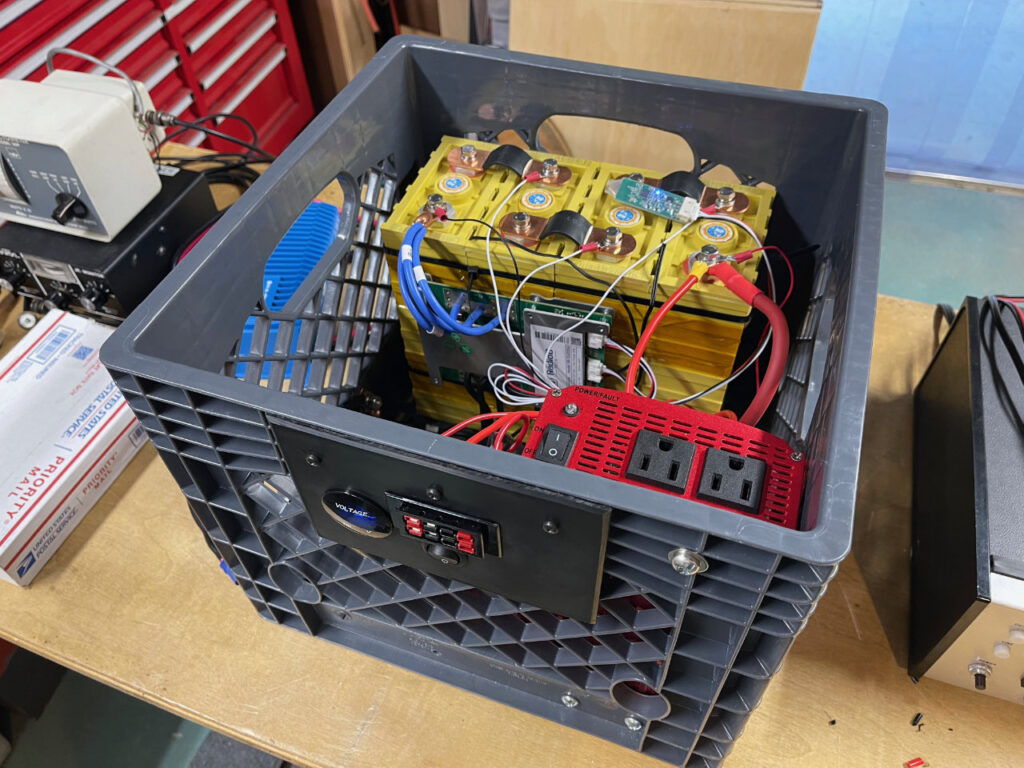

Really Great Lithium Ion Solar Battery: Copper Bus Bars

After building a wooden enclosure for the Lithium Ion Solar Battery, it was time to think about copper bus bars to connect all those cells together. This requires a little math, since the bus bars have to be big enough to handle current demand, but not too big — copper is expensive!

Continue reading →